STAHL » Product » Flatwork ironers » G-line

STAHL G-line is recognized to grant an unmatched ironing finish, thanks to a specifically studied pressure roller that allows treating even the most complex fabrics. Moreover, is has been designed looking at the maximum ease of access to all components for ordinary maintenance.

Suitable for: Linen of any kind, delicate fabrics or once difficult to treat such as lines, table cloths with embroideries or made of composites fabrics (like polyester on one side and cotton on the other) as well as duvet covers!

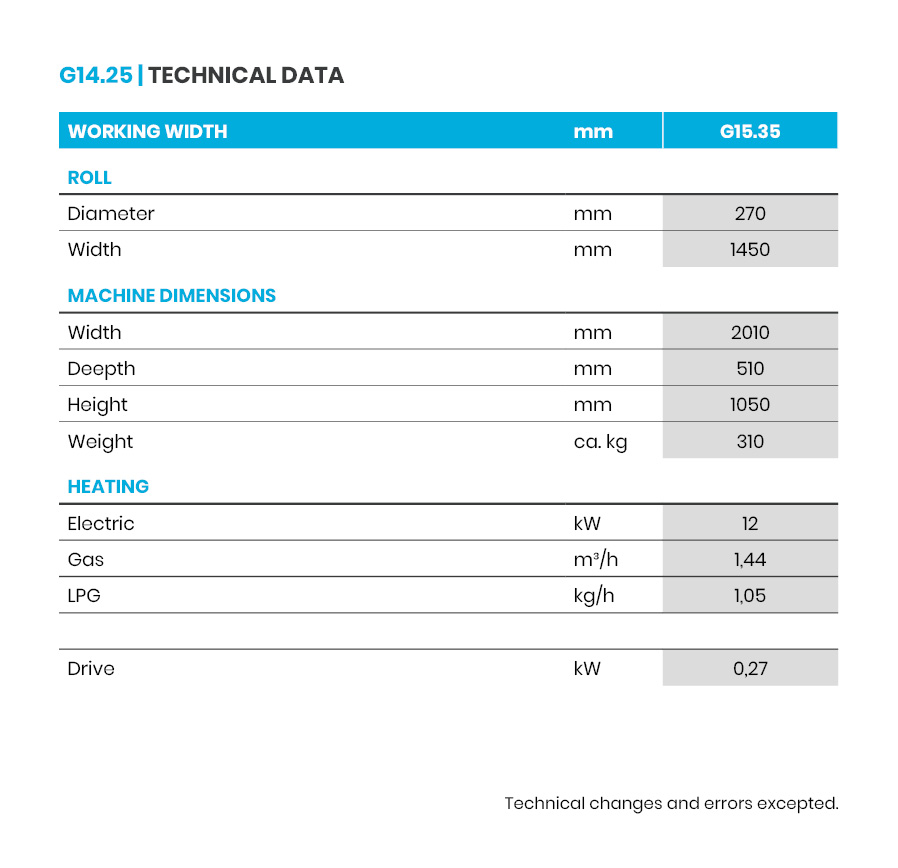

Thanks to the extremely precise temperature control achieved, heating power need for electricals headed version is just 12 kW, while the headed version only needs 1,05 kg/h of LPG for the same performance.

The “air blades” system grants an extra-efficient steam extraction compared to the traditional pipes with round holes, thanks to a wider suction surface. It limits at the same time the volume of lint being able to reach the motors, reducing maintenance operations frequency.

No more rubber padding for belts draft rollers, but knurled metal, which grants grip and eliminates one of the most frequent maintenance operations.

The smart electronics used for the G-line has a wide and user friendly control panel which shows clear indications of ironing parameters as well as smart diagnostics.

The G-line has been designed looking at the maximum ease of access to all the components for ordinary maintenance purpose.

G14.25 features a 35% wider contact surface between the linen and the roller compared to similar models on the market. This boosts the productivity up to 25 kg/h, resulting in 20 tons of ironed linen more every year (250 working days, 8 hours/day shifts).

It irons and dries in one single passage single-layer linen straight out form the high-spin washer extractor, which reduces processing time significantly.

Although G14.25 “only” features a roller width of 1,45m, it can process almost any kind of linen, up to king size bed sheets. This model grants an excellent finish on any type, including the delicate or difficult to treat ones, such as lines, table cloths with embroideries or made of composites fabrics (like polyester on one side and cotton on the other) as well as duvet covers.

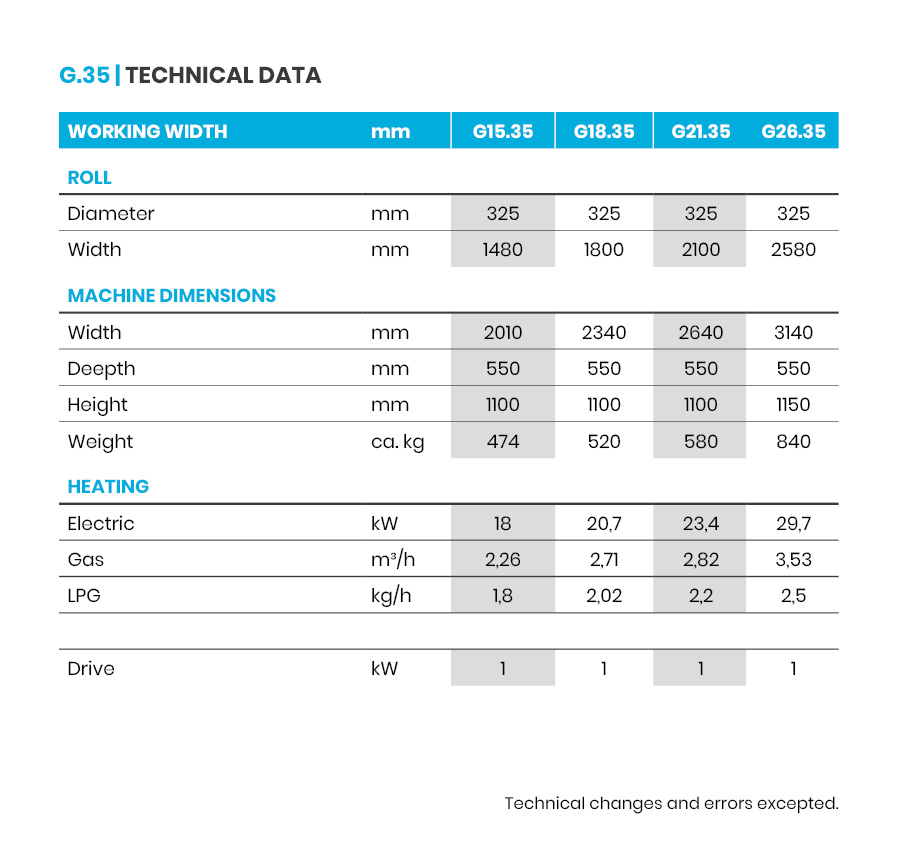

G.35 line is recognized to grant an unmatched ironing finish, thanks to a specifically studied pressure roller that allows treating even the most complex fabrics. It features a tremendously efficient temperature control, with reactive sensors and an excellent management of power installed, that allow obtaining an ideal temperature distribution across the whole ironing surface.

The “air blades” system grants an extra-efficient steam extraction compared to the traditional pipes with round holes, thanks to a wider suction surface.

The gas heated version uses an in-house developed patented burner, realized with the most modern technologies and materials to grant the perfect temperature control and maximum lifespan.

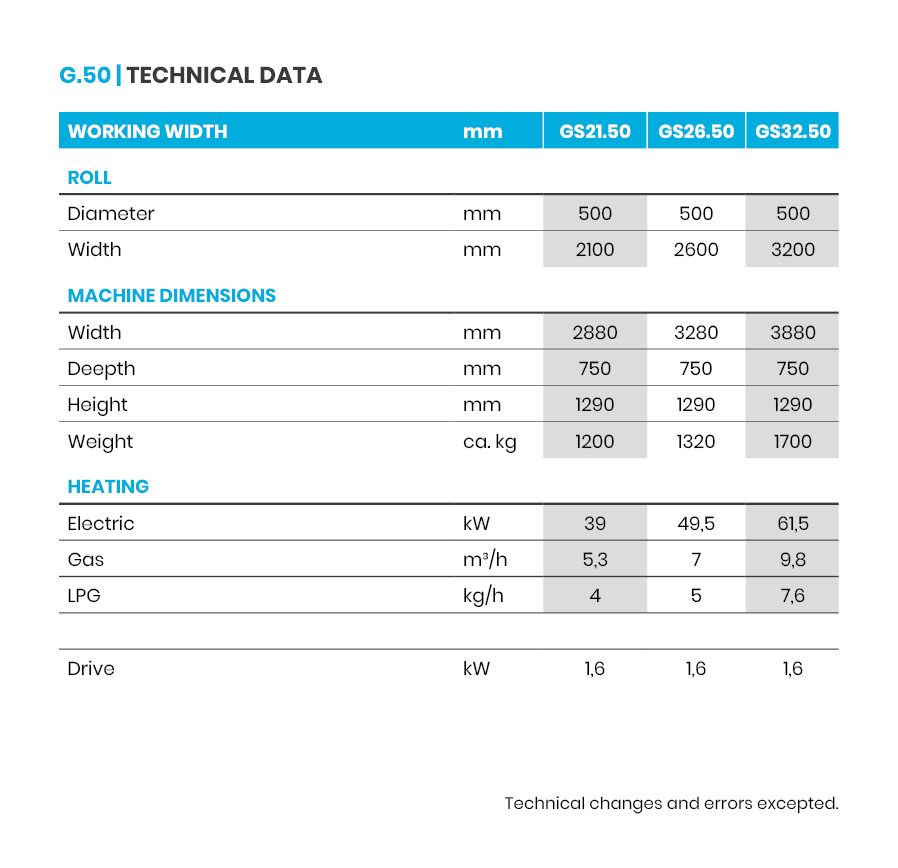

The newly, specially designed, extra-wide suction hood of the G.50 efficiently collects the seam flow and conveys it into the extraction piping. Thanks to the special design, there is no heat dispersion since the hood will extract only the humidity without affecting the temperature of the cylinder. Moreover, the drying times will shorten due to the extra-wide extraction surface. The water will evaporate very quickly from the linen and the belts, allowing working at a higher ironing speed.

The G.50 is strongly built even to the smallest detail: High quality Nomex ironing belts and lint filters will expand its lifespan. The knurled metal instead of rubber paddings for belts draft rollers, grants grip and eliminates one of the most frequent maintenance operations.

The smart electronics used for the G-line has a wide and user friendly control panel which shows clear indications of ironing parameters as well as smart diagnostics.

Unsere Produktion in Sindelfingen, verrät viel über die Qualität unserer Produkte.

In unserem Film nehmen wir Sie mit hinter die Kulissen.

Mit dem Laden des Videos akzeptieren Sie die Datenschutzerklärung von YouTube.

Mehr erfahren

We use cookies on our website. Some of them are essential, while others help us improve this site and your experience. If you are under 16 and wish to give consent to optional services, you must ask your legal guardians for permission. We use cookies and other technologies on our website. Some of them are essential, while others help us to improve this website and your experience. Personal data may be processed (e.g. IP addresses), for example for personalized ads and content or ad and content measurement. You can find more information about the use of your data in our privacy policy. You can revoke or adjust your selection at any time under Settings.

If you are under 16 and wish to give consent to optional services, you must ask your legal guardians for permission. We use cookies and other technologies on our website. Some of them are essential, while others help us to improve this website and your experience. Personal data may be processed (e.g. IP addresses), for example for personalized ads and content or ad and content measurement. You can find more information about the use of your data in our privacy policy. In this section you are given an overview of all cookies used. You can give your consent to entire categories or display further information and thus only select certain cookies.